- Home /

- Blog List /

- How to Reduce Risk through managing trip and slip environments, and improved awareness.

Shop Now

- Air Movers & Dehumidifiers

- Automotive Care

- Bin Liners

- Bulk Deals

- Carpet Cleaning Chemicals

- Carpet Extractors

-

Cleaning Chemicals

- Acid Cleaners

- Air Fresheners & Odour Control

- Aircon Cleaning Chemical

- Bathroom Cleaning Chemicals

- Carpet Cleaning Chemicals

- CHEMICAL DISPENSERS

- Degreaser Chemicals

- Descaler Chemicals

- Disinfectant Chemicals

- Fire Iron & Rust Removal

- Floor Care & Maintenance

- Floor Cleaning Chemicals

- Furniture Cleaning Chemicals

- General Cleaning Chemicals

- Graffiti Removers

- Insecticides & Bug Repellants

- Kitchen Cleaning Chemicals

- Laundry Detergents & Softeners

- Leather Cleaners

- Metal & Steel Cleaners

- Mould Removal Chemicals

- Outdoor Floor Chemicals

- Sanitisers & Sanitising Agents

- Spa Cleaning Chemicals

- Spray & Wipe Chemicals

- Stain Removal Chemicals

- Tile Cleaning Chemicals

- Window Cleaning Chemicals

- Enviro Friendly Products

- Equipment Hire

- Floor Care & Maintenance

- Floor Sanders

- Gloves

- Hand Dryers

- Hospitality

- Hotel/Motel Guest Supplies

- Janitorial Products

- Machine Spares & Accessories

- Mats & Matting

- Mats and Matting

- Microfibre Cloths/Pads/Holders

- Paper Products

- Polishers & Burnishers

- Pressure Washers

- Protective Clothing

- Scrapers & Blades

- Scrubbers

- Steamers and Steam Cleaners

- Sweepers

- Vacuum Accessories & Bags

- Vacuum Cleaners

-

Washroom Supplies

- Air Fresheners-Cans & Refills

- Body Wash & Shampoos

- Facial Tissues

- Hand Soap

- Hand Soap Dispensers

- Hand Towel

- Hand Towel Dispensers

- Insecticides & Bug Repellants

- Protective Hand Creams

- Sanitary Bins & Consumables

- Sanitisers & Sanitising Agents

- Toilet Bowl Clips

- Toilet Paper

- Toilet Paper Dispensers

- Urinal Screens

- Window Cleaning

- Wipes

Blog Archives

Blog Categories

How to Reduce Risk through managing trip and slip environments, and improved awareness.

Reduce Saftey Hazards - Saftey Signs & OHS

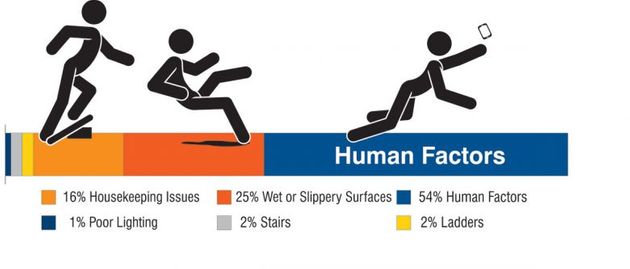

At Rapid Clean, we regularly have customers seeking guidance on reducing slip risk to avoid injuries and legal liability. Dry surfaces quickly become hazardous when wet. Surfaces can be treated with slip-resistant chemicals, have a material applied to them, or be physically altered. Improving user awareness helps, but a business unit operator must provide a practical safe environment.

Both operators and users are legally and morally responsible to manage risks associated with trip and slip hazards. Australian Standard 4586 for slip resistance is the legal standard. Being aware of risks allows everyone to take constructive steps to identify hazards and take steps to change surfaces or contact points, as well as educate exposed users. There are useful government federal and state guidelines to refer to, and private specialists to engage in.

The hierarchy of controls are:

-

Identify and Eliminate the hazard.

-

Substitution

-

Isolation

-

Engineering Controls

-

Administrative Controls

-

Personal Protective Equipment

Identifying slip and trip hazards

Common slip hazards include:

-

spills of liquid or solid material

-

wet cleaning methods

-

wind-driven rain or snow through doorways

-

a sudden change in floor surface, for example, joins between carpet and polished timber

-

change from wet to dry surface

-

dusty and sandy surfaces

-

the incline of a ramp

-

loose or bumpy flooring

-

low light levels

-

use of unsuitable footwear.

Common trip hazards include:

-

ridges in floors or carpets

-

worn floor coverings or broken tiles

-

potholes and cracks in floors

-

changes in floor level

-

thresholds and doorstops

-

floor sockets and phone jacks

-

cables from power extension units

-

loads that obstruct vision

-

obstacles in traffic areas

Australian Standards (AS) for Slip Resistance previously required a minimum coefficient of friction - wet of not less than 0.4 the current standard is now categorised into 5 classes.

These are: (Four S rubber)

AS4586 is available from CSIRO or Standards Australia.

In addition to the Pendulum Test changes, Ramp Tests (oil and wet barefoot) have been introduced. The Ramp Tests have different commercial classifications (refer A.S. HB 197) based on different applications/areas requiring higher or lower degrees of slip resistance, i.e. a fast-food kitchen would require a higher degree of slip resistance than a canteen. A Pendulum BPN rating defines the Slip Resistance of the pedestrian surface.

At Rapid Clean Newcastle we supply chemicals and equipment to clean and maintain surfaces to reduce slip risk. Chemicals available include permanent sealers with slip resistance, cleaning chemicals that leave a mild residue. Some manufacturers provide specific slip resistance subject to surface conditions. Rapid Clean also supplies safety signs.

For testing and floor treatment, there are third party specialists. Slip measurement using pendulum testing is very specialized. Treatments like abrasive strips, actual grinding or etching, are possible.

For more information download the slips and trips fact sheet from Safe Work Australia

Join us on socials |

|