- Home /

- EN 388 Glove Standard Explained - RapidClean Newcastle

Shop Now

- Air Movers & Dehumidifiers

- Automotive Care

- Bin Liners

- Bulk Deals

- Carpet Cleaning Chemicals

- Carpet Extractors

-

Cleaning Chemicals

- Acid Cleaners

- Air Fresheners & Odour Control

- Aircon Cleaning Chemical

- Bathroom Cleaning Chemicals

- Carpet Cleaning Chemicals

- CHEMICAL DISPENSERS

- Degreaser Chemicals

- Descaler Chemicals

- Disinfectant Chemicals

- Fire Iron & Rust Removal

- Floor Care & Maintenance

- Floor Cleaning Chemicals

- Furniture Cleaning Chemicals

- General Cleaning Chemicals

- Graffiti Removers

- Insecticides & Bug Repellants

- Kitchen Cleaning Chemicals

- Laundry Detergents & Softeners

- Leather Cleaners

- Metal & Steel Cleaners

- Mould Removal Chemicals

- Outdoor Floor Chemicals

- Sanitisers & Sanitising Agents

- Spa Cleaning Chemicals

- Spray & Wipe Chemicals

- Stain Removal Chemicals

- Tile Cleaning Chemicals

- Window Cleaning Chemicals

- Enviro Friendly Products

- Equipment Hire

- Floor Care & Maintenance

- Floor Sanders

- Gloves

- Hand Dryers

- Hospitality

- Hotel/Motel Guest Supplies

- Janitorial Products

- Machine Spares & Accessories

- Mats & Matting

- Mats and Matting

- Microfibre Cloths/Pads/Holders

- Paper Products

- Polishers & Burnishers

- Pressure Washers

- Protective Clothing

- Scrapers & Blades

- Scrubbers

- Steamers and Steam Cleaners

- Sweepers

- Vacuum Accessories & Bags

- Vacuum Cleaners

-

Washroom Supplies

- Air Fresheners-Cans & Refills

- Body Wash & Shampoos

- Facial Tissues

- Hand Soap

- Hand Soap Dispensers

- Hand Towel

- Hand Towel Dispensers

- Insecticides & Bug Repellants

- Protective Hand Creams

- Sanitary Bins & Consumables

- Sanitisers & Sanitising Agents

- Toilet Bowl Clips

- Toilet Paper

- Toilet Paper Dispensers

- Urinal Screens

- Window Cleaning

- Wipes

Blog Archives

Blog Categories

EN 388 Glove Standard Explained

The European Standard EN388 (2003) covers the test requirements for safety gloves that are sold as protection against mechanical risks. It is generally accepted that the majority of occupational hand injuries are caused by cuts and abrasions, with most of the more serious injuries due to cuts.

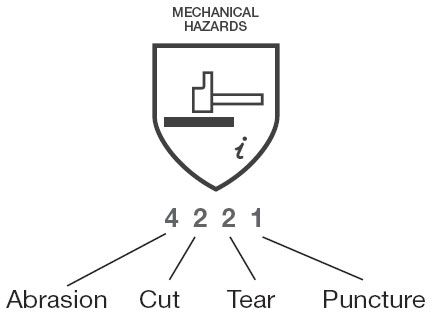

The EN 388 gloves are rated using four numbers; these numbers tell you how resistant the gloves are to mechanical hazards. You can use this information to ensure that your workers are protected in an appropriate way.

Work gloves that conform to EN 388 will be marked with this shield.

Under the shield will be four numbers. These show the level of protection according to EN388. Some gloves may be marked ‘x’ for a particular category. This means that this glove was not tested for that category.

Abrasion Resistance

The first number in EN 388 tells you how well the gloves resist abrasion. The number will vary between one and four. Abrasion resistance is important for all types of handling but is especially important for handling rough materials, such as bricks. It is important to have a high abrasion rating on gloves used in work areas such as gardening and construction work.

Blade Cuts Resistance

The second number in the EN 388 rating shows you the gloves’ resistance to blade cuts. This number ranges between one and five. Work gloves that have a higher rating in this category provide better protection against sharp objects, such as knives and glass. Gloves with a high level of blade cut resistance are ideal for workers who handle sheet metal, glass, and sharp tools.

Tear Resistance

The gloves’ resistance to tears is shown by the third number is the EN 388 rating. This number ranges between one and four. Gloves with a high level of tear resistance are very durable and will withstand demanding work such as construction, landscaping, and heavy handling.

Puncture Resistance

The final number in the EN 388 rating indicates the gloves’ resistance to punctures. This number will be between one and four. Gloves with high levels of puncture resistance provide greater protection against hazards such as needles, thorns, and syringes. This type of glove is ideal for medical and waste work.

To choose the correct type of work gloves, it is essential to consider the type of task for which they will be used. By assessing the types of hazards to which workers will be exposed, you will understand the type of protective gloves they will need.

Once a glove has been tested its performance will be represented using the EN388 icon. This icon must be printed on each glove so that it is easy to tell how much resistance the glove provides against the four mechanical risks.

While the maximum score on each performance test would be 4544 this is not to be regarded as the ‘best’ score. Each task will have different risks involved and therefore need a glove with suitable attributes. For example, if you are selecting a glove to use while painting walls then you’ll be very interested in the flexibility and durability of the glove, but not so concerned about its resistance to cuts and punctures. In this case, a glove with an EN388 rating of 4131 may be the best for the task.

Why is EN388 testing important?

The EN388 Standard tests reflect the hazards that glove wearers are likely to face in the widest range of handling tasks across the broadest range of industries. Presenting the results of these tests as performance numbers – and printing the performance icon on each glove – makes it easier to assess the suitability of a glove for a particular task.

GLOVES AVAILABLE TO PURCHASE ONLINE

|

|

|

|

Join us on socials |

|